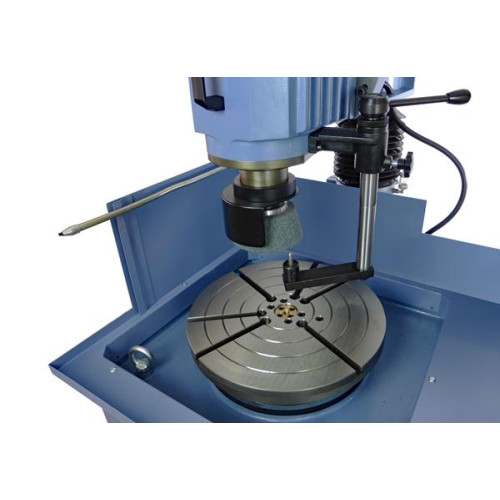

COMEC RTV600 FLYWHEEL GRINDER

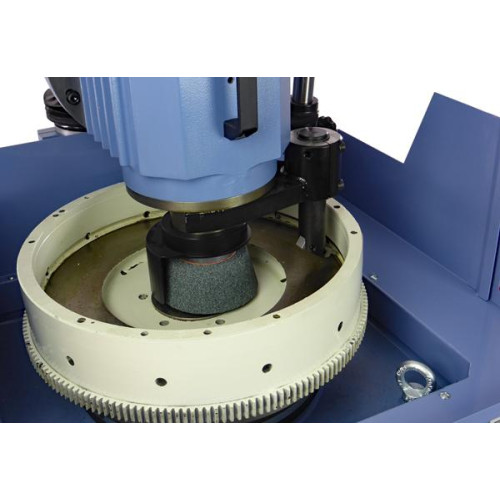

The grinding machine RTV600 represents the best and most advanced solution in terms of reconditioning of flywheels, clutch friction plates and pressure plates in industrial vehicles.

Description

The grinding machine RTV600 represents the best and most advanced solution in terms of reconditioning of flywheels, clutch friction plates and pressure plates in industrial vehicles. RTV600 it is also suitable for fine grinding of any other circular piece lke discs, rings or flanges.

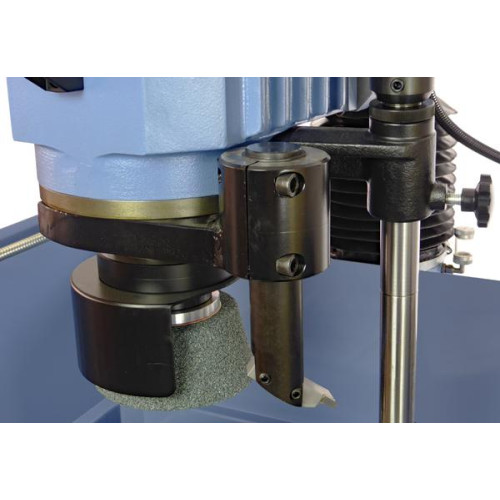

The flywheel surface grinder offers a high rigidity torsion, thanks to the use of cast iron for the base. The rotary table lies on a surface constantly lubricated with oil that helps in reducing the friction and preserving the machine at the same time and it can also be supplied with a magnetic plate.The 4 kW motor grants a sufficient power to work any kind of material with high depths of cutting. For all these reasons the RTV600 meets the requirements of the most demanding mechanics.

Head power feed

Splash and safety guard

Cooling plant complete with pump and settling tank

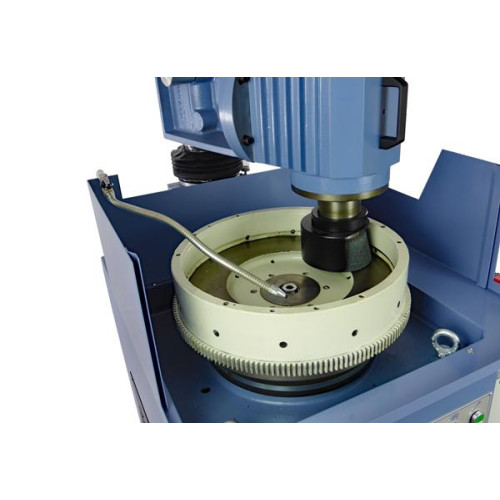

Grinding wheel dresser

Wheel dressing diamond

Cup grinding wheel for cast iron

Set of centering cones

Set of supporting rings

Dial gauge with support

Blocking screws

Lubricant for slides

Emulsifiable oil

Wrench set

Technical Characteristics

| Maximum grinding diameter | 630mm |

| Rotary table diameter | 450mm |

| Max height table-weight | 215mm |

| Taper grinding wheel speed | 150mm |

| Rotary table speed | 16 rpm |

| Grinding wheel speed | 2800rpm |

| Power head motor RTV 600 / RTV 612 | 5.5hp (4kw) / 12hp (9kw) |

| Power table motor | 0.75hp (0.55kw) |

| Power rapid feed head motor | 0.25hp (0.18kw) |

| Dimensions (LxWxH) | 1200x900x1600mm |

| Weight | 710kg |